CHICKEN LOADER

Alle 3 resultaten

The GTC Agricultural automatic loading

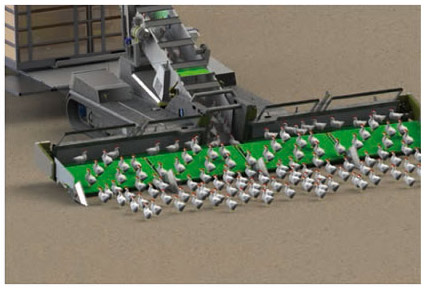

Catching

The machine is stationed inside the poultry shed and prepared by opening the two wings of the front collection head, which are formed of individual blocks of conveyor belts. The operator starts the machine: Apollo activates the conveyor belts and slowly moves towards the animals, allowing them to climb onto the collection belts in a natural way that requires no mechanical force. These belts deposit the birds, without subjecting them to any sudden or stressful movements, onto the two transverse belts that lead to the central channel.

The machine is stationed inside the poultry shed and prepared by opening the two wings of the front collection head, which are formed of individual blocks of conveyor belts. The operator starts the machine: Apollo activates the conveyor belts and slowly moves towards the animals, allowing them to climb onto the collection belts in a natural way that requires no mechanical force. These belts deposit the birds, without subjecting them to any sudden or stressful movements, onto the two transverse belts that lead to the central channel.

Caging

The animals then continue into Apollo’s central channel, where they are carefully transported to the upper part of the machine. Here, the caging belt directly deposits the birds into the container. With simple controls, the operator can raise or lower the belt, or move it nearer or further away. With the same controls, the operator can also move onto the next crate and start or stop the entire machine and all of its collection belts. Thanks to the automatic weighing system, the machine stops when it reaches the preset value, guaranteeing compliance with every regulation in force regarding animal density in the containers.

The animals then continue into Apollo’s central channel, where they are carefully transported to the upper part of the machine. Here, the caging belt directly deposits the birds into the container. With simple controls, the operator can raise or lower the belt, or move it nearer or further away. With the same controls, the operator can also move onto the next crate and start or stop the entire machine and all of its collection belts. Thanks to the automatic weighing system, the machine stops when it reaches the preset value, guaranteeing compliance with every regulation in force regarding animal density in the containers.

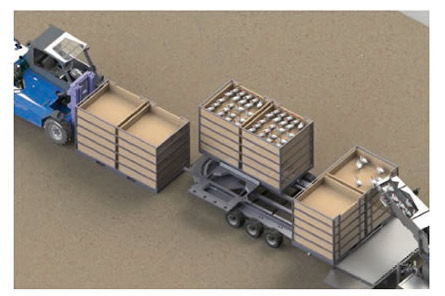

Carousel

The containers are positioned on a carousel, which, with the aid of automatic movement, allows for a continuous loading process.

This is where the core of the innovative animal weighing system is located, which allows for the instant verification that the correct weight of animals has been deposited into each crate. Once a module is full, it is then ready for collection by the forklift, which places it on the lorry outside the poultry shed.