1. Agility

Quick and highly manoeuvrable, thanks to the short turning radius and reduced dimensions.

2. Loading speed

Comfortable driver’s seat. Minimized in-cab vibrations. Easy access to the driver’s seat. Simple joystick with forward/reverse command.

3. Created for the poultry industry

Triple air filter. Protected blue headlights.

4. Improved animal welfare

Smooth movements. Forks with shock absorbers for container stability during transport.

5. Straightforward maintenance

Simple maintenance of the engine and vital moving parts. Completely hydraulic. Essential electrical circuit.

6. Stability

Four wheel drive. Low centre of gravity. Centrally positioned engine.

7. Safe

360° visibility. Controlled and precise maneuverability.

8. Less damage to containers and trucks

Precise maneuvering during container loading/unloading.

All the answers for your questions.

HOW MUCH MAINTENANCE DOES THE AGILE NEED?Thanks to the simplicity of the electric and hydraulic systems, maintenance requirements are drastically reduced as compared to industry-standard forklifts. The machine’s motor and vital moving parts are easily accessible.

WHAT IF MY WAREHOUSE HAS SEVERAL FLOORS, A LOW CEILING OR PILLARS?

Agile is a short, compact machine and highly manoeuvrable. Its wide steering range makes it easy to move, even between obstacles or pillars.

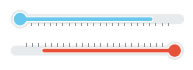

WHAT IF IT GETS VERY COLD OR VERY HOT?

The Agile has been designed to work in temperatures ranging from -40° C (-40° F) to +50° C (122° F).

AND IN TERMS OF CLEANING?

Cleaning the Agile is extremely easy. Its body and main parts can be washed with water and disinfectant, significantly increasing biosecurity.

HOW MUCH FUEL DOES THE AGILE USE?

The Agile has been built to transport containers efficiently and quickly, with a powerful engine. But with a low weight to power ratio, the Agile uses significantly less fuel as compared to any other forklifts in the same class.

The Agile has been designed to work in temperatures ranging from -40° C (-40° F) to +50° C (122° F).

AND IN TERMS OF CLEANING?

Cleaning the Agile is extremely easy. Its body and main parts can be washed with water and disinfectant, significantly increasing biosecurity.

HOW MUCH FUEL DOES THE AGILE USE?

The Agile has been built to transport containers efficiently and quickly, with a powerful engine. But with a low weight to power ratio, the Agile uses significantly less fuel as compared to any other forklifts in the same class.

| PERFORMANCE | Maximum capacity: 2,000 Kg (4,410 lbs) | HYDRAULIC SYSTEM | Hydrostatic pump with fixed cylinder capacity: 65 l | |

| Max. lifting height: 3,050 mm* | Maximum pressure: 160 bar | |||

| Max. machine height: 1,650 mm o 1,800 mm | ||||

| Fork inclination angle: +10° / -10° | MOTOR | Model: Perkins 804 D | ||

| Breakout force: 2,400 daN | Maximum power: 47 kW (64 Hp) | |||

| Total weight unloaded: 3,700 Kg | Revolutions per minute: 2,600 max | |||

| Maximum speed: 27 km/h (17 mph) | Operation: 4 stroke diesel | |||

| Cooling: liquido | ||||

| REFUELLING | Fuel tank: 62 l | Cylindres: 4 vertical in line | ||

| Hydraulic tank: 120 l | Cylinder capacity: 3,300 cc | |||

| Consumption: 13.3 l/h at full power | ||||

| STANDARD EQUIPMENT | Forks, sideshift, hydraulic socket, triple air filter, padded seat | |||

| TRANSMISSION | Rexroth hydrostatic pump with variable cubic capacity | |||

| ADDITIONAL INFORMATION | Cleaning: High pressure air and water | 4 hydraulic Rexroth motors | ||

| Electrical joystick command | ||||

| Electrically activated hand brake | ||||

| TYRES | Front/Back: 10.0 / 75 – 15.3 | |||

| OPTIONAL EXTRAS AND ACCESSORIES | Cab lowering kit, cab closing kit, heating, air conditioning (heating included) ), fork shock absorber, rotator, 1,400 l bucket, ATF XT hydraulic oil for low temperatures |

Video

For more information about this product? Please contact us